Learning Courses, Certifications, Processes

Manufacturing Jewellery: The Complete Guide

Eric Walker

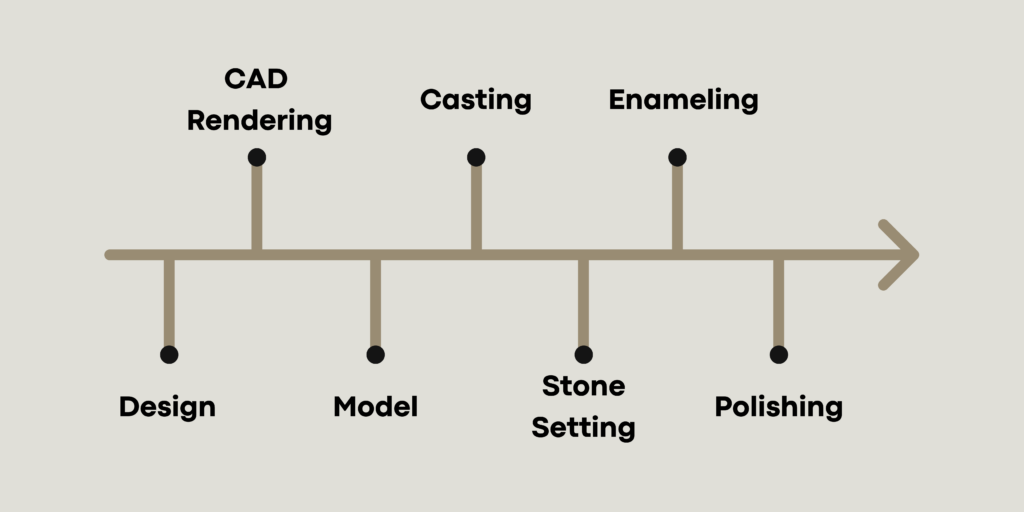

April 02, 2024Jewellery manufacturing is a captivating blend of artistry, precision and craftsmanship. It requires an intricate understanding of materials, design, and technique to transform raw materials into stunning pieces of wearable art. This process is not just about crafting beautiful accessories, but also about capturing the essence of beauty, elegance, and personal expression.

The Birth of a Jewellery Design

In the dynamic world of jewellery manufacturing, the birth of a design marks the inception of a captivating journey from concept to creation. This intricate process involves meticulous planning and creativity, culminating in exquisite pieces that captivate hearts and minds.

Inspiration Strikes

The design journey begins with a spark of inspiration – a moment of creativity that sets the tone for the entire process. Whether it’s a natural element, a historical reference, or a modern trend, inspiration plays a vital role in shaping the design.

Sketching and Conceptualization

Once you capture the inspiration, designers begin sketching and conceptualizing the design. This phase involves translating ideas into visual representations, exploring different shapes, patterns, and details to bring the vision to life.

Material Selection and Prototyping

After finalizing the design concept, the next step is selecting the right materials that will enhance the beauty and durability of the piece. Prototyping allows designers to test the design in real-life scenarios, ensuring that it meets both aesthetic and functional requirements.

Crafting and Finishing

The final stage involves meticulous craftsmanship and attention to detail. Skilled artisans bring the design to life, using traditional techniques or modern technology to create stunning jewellery pieces. The finishing touches add a touch of perfection, ready to adorn those who appreciate fine artistry.

In the dynamic world of jewellery manufacturing, the birth of a design marks the inception of a captivating journey from concept to creation. This intricate process involves meticulous planning and creativity, culminating in exquisite pieces that captivate hearts and minds.

Inspiration Strikes

The design journey begins with a spark of inspiration – a moment of creativity that sets the tone for the entire process. Whether it’s a natural element, a historical reference, or a modern trend, inspiration plays a vital role in shaping the design.

Sketching and Conceptualization

Once the inspiration stage is complete, designers begin sketching and conceptualizing the design. This phase involves translating ideas into visual representations, exploring different shapes, patterns, and details to bring the vision to life.

From Paper to Prototype

Once the design is finalized, it’s time to bring it to life. The prototype is often made using less expensive materials before crafting the final piece.

- Wax Carving: In this traditional technique, a wax model of the design goes through hand-carving process. This model is essentially a 3D blueprint for the final piece.

- 3D Printing: With advancements in technology, 3D printers can now create highly accurate wax or resin models based on CAD designs.

Casting the Design

The next step is Jewelry casting, where the design is transformed from a wax or resin model into metal. This is done through a process called ‘lost wax casting’ or ‘investment casting’.

Investment Casting

Investment casting, also known as lost-wax casting, is a popular method in jewelry manufacturing due to its precision and intricate detailing capabilities. This process involves creating a wax model of the jewelry piece, which is then coated in a ceramic shell. The wax is melted out, leaving a cavity in the shape of the jewelry. Molten metal is poured into the cavity, solidifying to form the final piece.

Investment casting allows for complex designs and fine details that are hard to achieve through other methods. It is ideal for producing high-quality jewelry with intricate patterns, textures, and delicate features. This technique is favored by jewellery designers for its ability to create unique and custom pieces that stand out in the market. Investment casting ensures a high level of accuracy and consistency, making it a sought-after technique in the jewelry industry.

Finishing Touches

After casting, the piece undergoes various finishing processes to enhance its beauty.

Filing and Polishing

Filing and polishing are crucial techniques in jewelry making to enhance the appearance and quality of the final piece.

The filing involves using a file, a tool with abrasive surfaces, to shape and smooth metal surfaces by removing excess material and refining edges. This process helps in achieving precise shapes and dimensions for intricate designs.

Polishing is the next step after filing, where the jewelry piece get the smoothing further. This is to create a shiny and lustrous finish. Various polishing compounds and tools like buffing wheels or cloths are used to remove scratches, oxidation, and any surface imperfections.

Together, filing and polishing transform rough metal into a refined and elegant piece of jewelry that shines brilliantly. These techniques require skill, patience, and attention to detail to create stunning jewelry pieces that captivate and delight wearers.

Stone Setting

Stone setting in jewelry manufacturing is a crucial and intricate process that requires precision and skill. It involves securely placing gemstones onto metal jewelry pieces, enhancing their beauty and value. Various techniques, such as prong setting, bezel setting, pave setting, and channel setting, is being in use to hold stones in place effectively. Each method offers a unique aesthetic appeal and level of security for the gemstone.

Prong setting uses metal claws to grip the stone, allowing maximum light to pass through for optimal sparkle. Bezel setting encases the gemstone in a metal rim, offering a sleek and modern look. Pave setting involves closely arranging small stones to create a glittering surface. Channel setting places stones between two metal walls for a smooth and elegant finish.

Mastering stone setting is essential for jewelry artisans to create stunning pieces that showcase the beauty of gemstones while ensuring their durability and longevity.

Quality Inspection

Quality inspection in jewellery manufacturing is a crucial process to ensure that the final products meet high standards of craftsmanship and aesthetics. Inspecting jewellery involves examining each piece for flaws, such as irregularities in gemstone setting, scratches, or imperfections in metalwork. Quality inspectors use magnifying tools to scrutinize intricate details and verify that the jewellery matches design specifications.

Additionally, inspections involve testing the durability of clasps, hinges, and other functional components to guarantee longevity. You document any deviations from quality standards and implement corrective measures to maintain consistency across production batches.

By conducting thorough quality inspections, manufacturers uphold their reputation for producing exquisite and durable jewellery pieces that delight customers. Investing time and resources in quality control ultimately leads to customer satisfaction and loyalty in the competitive jewellery market.

The Evolution of Jewellery Manufacturing

Over the years, jewellery manufacturing has evolved significantly. While ancient craftsmen relied solely on hand tools and their ingenuity, modern manufacturers now harness technology to enhance precision and efficiency without compromising on creativity and craftsmanship.

Despite these advancements, the essence of jewellery manufacturing remains unchanged. It’s still about transforming raw materials into exquisite pieces that tell a story, evoke emotions, and celebrate individuality.

The beauty of jewellery manufacturing lies in its ability to merge tradition with innovation, craftsmanship with technology, and artistry with engineering. It’s a testament to the timeless allure of jewellery and the skill and passion of those who bring these radiant pieces to life.

Summary

Manufacturing jewelry is a meticulous process that demands precision and skill. Craftsmen meticulously design and create intricate pieces, showcasing their artistry. Each piece tells a unique story, reflecting the craftsmanship and attention to detail. The blend of traditional techniques and modern technology ensures the creation of exquisite jewelry pieces that stand the test of time.Manufacturing jewelry is a meticulous process that demands precision and skill.

Craftsmen meticulously design and create intricate pieces, showcasing their artistry. Each piece tells a unique story, reflecting the craftsmanship and attention to detail. The blend of traditional techniques and modern technology ensures the creation of exquisite jewelry pieces that stand the test of time.

All Tags

Loading...

Loading...