The Guide to Precious Metal Refinery

The Mintly Team

February 13, 2023

Finding the Precious Metal Refinery near you is easy. This guide details the information about refining process and its various stages. It will help you understand the different types of precious metals, their properties, and how to refine them. You will also get practical knowledge on how to select a reliable refinery near you. You can find which companies offers quality services with competitive prices.

Precious Metals Refinery

This is a complex process that helps to purify and transform raw ore into the purest form of precious metals. Precious metal refiners are responsible for handling this delicate process taking valuable resources and turning them into something more valuable.

The essential steps within the refining process include melting, oxidizing, and electroplating. Once these processes are complete, it will be possible to return the metals back to their original state . The only much purer than before! Refinery experts must undertake rigorous quality control checks throughout the entire refinement procedure to ensure each batch meets industry standards.

Not only do refiners have expertise in this field but they also need to possess a high level of knowledge regarding the different types of precious metals available on the market today. They should also be familiar with safety protocols in order to guarantee that all materials remain safe during processing.

What is a Precious Metals Refinery?

A precious metals refinery is a company that specializes in the refining of precious metals such as gold and silver. Refining precious metals typically involves obtaining the raw material from different sources, chemically separating it into its component parts, and then recombining it into a purer form. The refined metal can then be used for various applications including jewelry manufacturing, electronic products, and other industries.

A precious metals refining company will take raw ore and convert it into an acceptable purity level for use in industry. The process begins by crushing the ore to a powder form which is then further processed using chemical processes to separate out the desired elements such as gold or silver. After this separation has taken place, the metal is melted down and recast in order to purify it even further.

Precious metals refineries are businesses that specialize in the refining and purification of precious metals such as gold, silver, platinum and palladium. Refining these materials involves melting them down to their purest form so they can be used for various purposes. Precious metal calculators are essential tools for those operating a precious metals refinery. These calculators are designed to help determine the value of a certain amount of these materials based on the spot price provided by various dealers or exchanges.

Processes & Practices: Overview

Precious metal refineries are highly specialized facilities that refine and purify valuable metals like gold, silver, platinum, and palladium. These refineries are dedicated to extracting the highest grade of precious metals from raw ore for use in a wide range of applications including jewelry, electronics, medical devices, and even coins. To ensure their products meet the highest standards of quality and purity possible, these industrial sites must adhere to strict processes and practices.

Refinery workers utilize specialized equipment such as furnaces, acids baths, electrolysis cells and assay laboratories in order to separate the precious metals from base materials. In addition to physical separation techniques it is also essential that chemical analysis be conducted on every sample throughout each step of the refining process. Many refineries employ highly trained chemists who supervise all testing procedures while others rely on independent third-party laboratories to confirm their results.

Factors to Consider: Quality, Cost, etc.

When considering precious metal melting points and refineries, there are a few important factors to consider. Quality is often the most important factor for many customers. Knowing that the materials used in refining will create top-tier results is essential when choosing a refinery. Cost is another consideration that should be taken into account. Striking a balance between quality and cost can be tricky, so it’s important to do your research and find out which refinery offers both quality and value in equal measure.

It’s also worth understanding the processes used by each refinery before making your decision. Different refineries may use different processes or techniques to refine the metal, so it’s best to compare them before proceeding with any purchase or transaction.

Working with Refineries: Steps & Tips

Precious metals refineries are essential for those working with gold and silver. Refineries provide a quick and easy way to refine gold and silver materials into pure forms of the precious metals. Working with refineries can be a daunting task, but it doesn’t have to be. By understanding some simple steps and tips, you can easily work with precious metal refineries.

The first step when working with refineries is research. It’s important to find out which refinery can best meet your needs in terms of purity levels, turnaround times, pricing, and more. Once you’ve found a reputable refinery that meets your criteria, the next step is to create an account or register for services at the refinery. After that comes the refining process itself; many refiners accept various types of raw material such as coins or jewelry for refining into pure gold or silver bars or coins.

Common Types of Precious Metals Refined

Precious metals are some of the most valuable materials on Earth, and many industries rely on these materials for their operations. Refining precious metals can produce a higher purity product that is used in numerous applications. Gold and silver are two of the most commonly refined precious metals, and those looking for gold and silver refinery services near them can find plenty of companies offering this service.

The refining process involves dissolving the metal in an acid to separate it from any impurities or contaminants, followed by filtering to remove unwanted particulates before recasting into bars or coins. Gold is typically refined using a chlorination process that involves treating it with chlorine gas under high temperatures until all contaminates have been removed. Silver refineries often use electrolysis which involves passing an electric current through a silver solution to separate out pure silver particles from other elements present in the ore.

Companies doing Precious Metals Refinery

The top seven gold and silver refiners in the world are

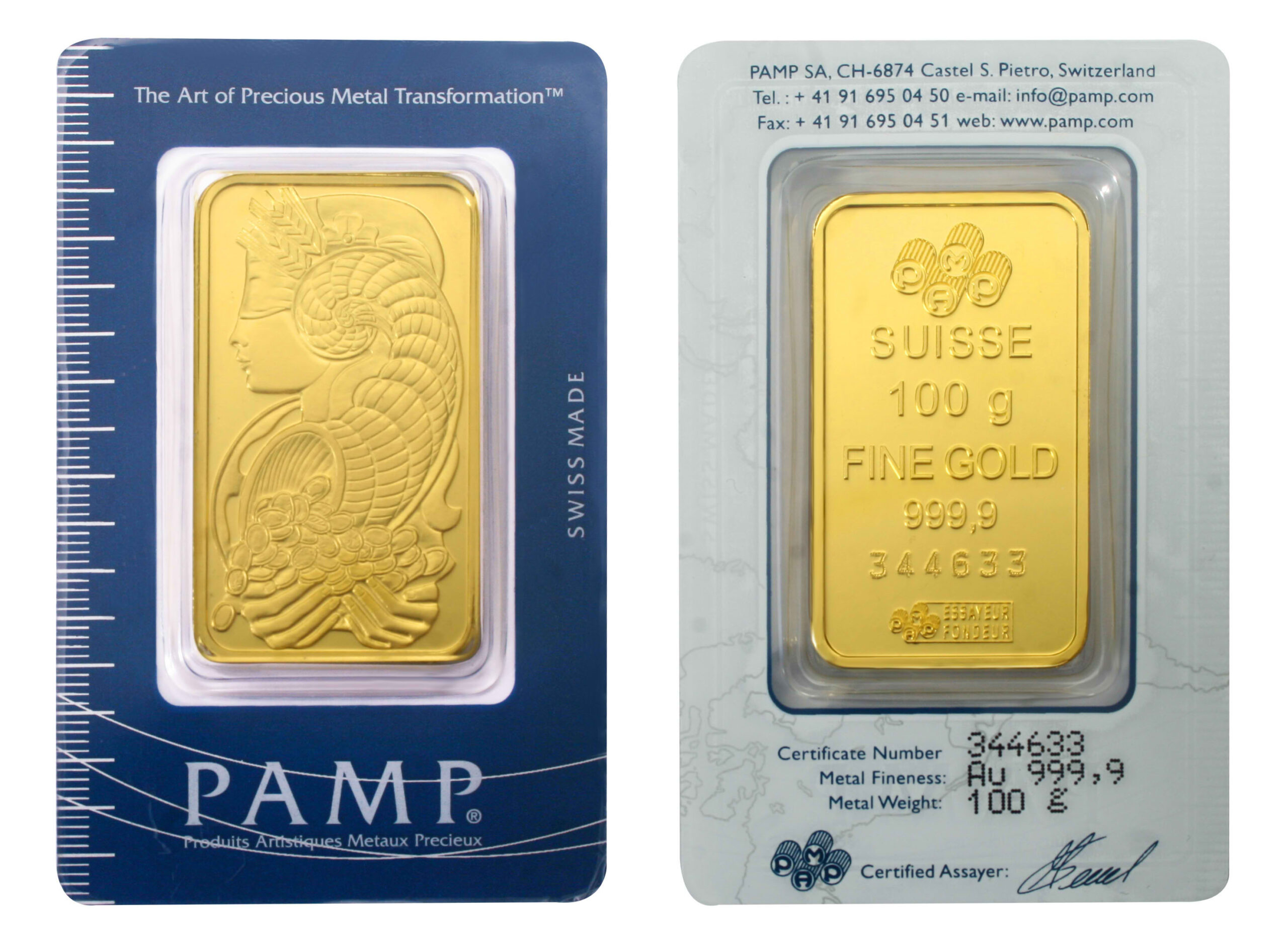

PAMP, Switzerland

Companies like PAMP, based in Switzerland, are at the forefront of this development, setting trends and leading advances in production techniques and technology. As one of the world’s leading refiners of gold, silver, platinum and palladium bars, coins and ingots, PAMP has been providing customers with quality products since 1977. Its commitment to excellence has resulted in accolades such as being awarded London Bullion Market Association (LBMA) Good Delivery status for its gold bars.

Valcambi, Switzerland

Valcambi is a precious metals refiner based in Balerna, Switzerland. The company was founded in 1961 and is one of the largest gold refiners in the world. Valcambi specializes in refining gold, silver, platinum and palladium for many industries including jewelry, electronics and automotive.

Valcambi provides services for minting coins and bars as well as developing products such as grain bars. The company also produces a variety of alloys that are used to create products ranging from medical instruments to industrial parts. With over 50 years of experience in precious metal refining, Valcambi has become an industry leader with customers around the world. Their advanced quality control systems ensure that they produce materials with precision and accuracy according to customer specifications.

Argor-Heraeus, Switzerland

Argor-Heraeus, the largest Swiss-based gold refiner in Europe, has been at the forefront of this industry since 1951. This company is renowned for its commitment to excellence and precision when it comes to precious metal refining, with a capacity to process up to 2,500 tonnes of gold and silver each year.

Argor-Heraeus’ expertise in precious metals extends beyond simple refining; they are also involved in minting coins and bars for investment purposes as well as providing services such as assaying and certification. Their commitment to quality control is evident in every step of their production process – from initial smelting all the way through to final packaging – ensuring that customers receive only the highest quality products.

Metalor Technologies, Switzerland

Metalor Technologies, headquartered in Switzerland, is one of the world’s leading companies in the precious metals industry. They specialize in refining and manufacturing gold, silver and other precious metals. Metalor works with both large industrial customers as well as smaller artisanal clients and has a presence around the world.

Utilizing state-of-the-art technology paired with decades of industry experience, Metalor strives to ensure quality in all their processes. From refining to minting services, they offer a comprehensive range of products across many different sectors including jewelry production, electronics manufacturing, watchmaking and more.

Heraeus, Germany

Founded in 1851, Heraeus has built a reputation for excellence in the production and processing of gold, silver, platinum and other rare elements.

Heraeus’ commitment to quality begins with its own mines in South America. The company sources its raw materials directly from these mines before refining them with sophisticated methods developed over almost two centuries of operation. This allows Heraeus to guarantee the purity and authenticity of each metal used in its manufacturing processes.

Tanaka, Japan

Tanaka Corporation, one of Japan’s leading companies in precious metals, is renowned for its high standards and quality products. Founded in 1885, Tanaka initially specialized in gold refining before expanding to encompass a broad array of products including coins, bars and medals.

Tanaka also offers customers access to state-of-the-art technology that ensures their products maintain reliable purity levels and continuous product consistency from batch to batch.

Rand Refinery, South Africa

Rand Refinery is one such company that has been at the forefront of precious metals market since founding in 1920. With its headquarters situated in Germiston, Rand Refinery is one of the largest gold refineries on the continent. It processes around 400 tonnes of gold each year. Rand Refinery produces over 9 million ounces of silver annually along with other platinum group metals.

Rand Refinery’s reputation as a major player in the precious metals space extends far beyond its South African borders. The refinery works closely with mining industry leaders from across Africa to ensure it can meet its customers’ demands for high-quality products that meet their exact specifications.

Refineries in the United States

REL is the world’s largest gold refiner who refine more than 2400 tons of precious metals per annum. Precious metals refinery (PMR) in Tucson is the process of extracting valuable metals from ore. This process can involve crushing, smelting, and separating the metals from ore. The company following this process to increasing their commercial value. Companies that specialize in this type of refining are an integral part of Tucson’s economy. They provide essential services to customers around the world.

For over 50 years, PMR has been buying diamonds, jewelry, gold, silver, platinum, watches, and coins. They use technologies such as ICP-MS (Inductively Coupled Plasma Mass Spectrometry) analytical equipment. PMR is able to provide fast and accurate results at competitive prices. Additionally, PMR employ experienced professionals who understand how to maximize the efficiency of each project. Also while maintaining stringent safety protocols.

One another company in the US is the United Precious Metals Refinery (UPMR). UPMR specializes in refining gold, silver, platinum, palladium, and rhodium. They make into various forms, from bars and coins to jewelry and other products.

They offer an array of services for customers interested in dealing with precious metals. This including refining services that involve analysis of metal samples as well as melting down scrap material. UPMR also provides assaying services to certify the purity of gold and other metals. Additionally, they offer minting services which include custom design options for coins or bars as well as packaging solutions

Benefits of Working with a Refinery

In conclusion, working with a refinery offers numerous benefits. It can help to reduce risk, improve efficiency and productivity, and increase profits. Additionally, it can allow for more specialized services and products, as well as better access to markets. Working with a refinery is an excellent way for companies to maximize their potential and increase their success. This involves complicated process and procedure for Procedure for Precious metal refining. It requires the skill of a precious metal professional refiners.

Final Thoughts

Refining precious metals is a complex process that requires expertise and attention to detail. This guide has provided valuable insights into the world of precious metals refinery, from understanding the types of metals to the refining methods involved. Armed with this knowledge, individuals can confidently navigate the refinery industry and unlock the value of their precious metals.

All Tags

Loading...

Loading...