In today’s highly competitive business landscape, effective production planning and control are crucial for the success of any manufacturing organization. To ensure efficient operations, companies rely on a variety of tools and techniques that help optimize their production processes. These tools not only streamline operations but also enhance productivity, reduce costs, and improve overall customer satisfaction. In this blog post, we will explore some of the essential production planning and control tools that are widely used in the industry.

1. Enterprise Resource Planning (ERP) Systems

Enterprise Resource Planning (ERP) systems are powerful tools that integrate various business processes and functions into a single, centralized platform. These systems play a crucial role in enhancing the efficiency and effectiveness of production planning and control processes within an organization.

One of the key modules of an ERP system that supports production planning and control is the Production Planning module. This module enables businesses to create and manage production plans, schedules, and workflows. It provides functionalities for capacity planning, material requirements planning, and resource allocation. By utilizing this module, organizations can optimize their production processes, minimize lead times, and ensure timely delivery of products to customers. Another essential component of an ERP system that aids in production planning and control is the Inventory Management module. This module allows businesses to keep track of their inventory levels, monitor stock movements, and manage reorder points. By maintaining accurate inventory data in real-time, organizations can avoid stockouts, reduce excess inventory costs, and ensure smooth production operations.

Another essential component of an ERP system that aids in production planning and control is the Inventory Management module. This module allows businesses to keep track of their inventory levels, monitor stock movements, and manage reorder points. By maintaining accurate inventory data in real-time, organizations can avoid stockouts, reduce excess inventory costs, and ensure smooth production operations.

Production Planning and Control

Furthermore, the ERP system’s Material Requirements Planning (MRP) module is instrumental in production planning and control. This module calculates the materials needed for production based on sales orders, current inventory levels, and production schedules. It helps organizations determine when and how much raw materials to procure, ensuring that production activities are not delayed due to material shortages.

The Shop Floor Control module within an ERP system also plays a vital role in production planning and control. This module provides real-time visibility into shop floor activities, allowing organizations to monitor production progress, track work orders, and allocate resources effectively. It enables better coordination between different departments involved in the production process, leading to improved productivity and reduced production cycle times.

Lastly, the Reporting and Analytics capabilities of an ERP system are crucial for production planning and control. These features provide comprehensive insights into key performance indicators (KPIs), such as production throughput, cycle times, and resource utilization. By analyzing these metrics, organizations can identify bottlenecks, make data-driven decisions, and continuously improve their production planning and control processes.

2. Material Requirements Planning (MRP) Systems

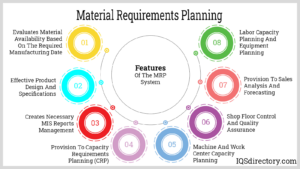

Material Requirements Planning (MRP) systems are essential production planning and control tools used by businesses to effectively manage their manufacturing processes. These systems enable companies to determine the necessary materials, quantities, and timing required to meet production demands.

MRP systems work by analyzing various factors such as sales forecasts, current inventory levels, and production schedules. By considering these factors, the system generates a comprehensive plan that outlines the materials needed at each stage of the production process. This plan helps companies optimize their inventory levels, minimize stockouts, and reduce carrying costs.

One of the key benefits of MRP systems is their ability to streamline the production planning process. By automating the calculations and analysis of material requirements, these systems save time and improve accuracy. This allows businesses to make informed decisions regarding purchasing, scheduling, and capacity utilization.

Furthermore, MRP systems facilitate effective communication and coordination among different departments within an organization. With real-time data insights, relevant stakeholders can collaborate more efficiently, ensuring that production plans align with overall business objectives.

In addition to aiding production planning, MRP systems also contribute to effective control over the manufacturing process. By tracking material availability, lead times, and production progress, these systems enable businesses to identify bottlenecks and take corrective actions promptly. This leads to improved efficiency, reduced waste, and enhanced customer satisfaction.

3. Capacity Planning Tools

Production Planning and Control Tools are essential for effective capacity planning in any organization. These tools provide valuable insights into the production process, allowing businesses to optimize their resources and meet customer demands efficiently. Here are some key points about capacity planning tools and their role in production planning and control:

Capacity planning tools help businesses determine the optimal level of resources required for production. They analyze historical data, demand forecasts, and other factors to estimate the capacity needed to meet customer orders.

These tools enable organizations to identify potential bottlenecks and constraints in the production process. By analyzing data such as machine utilization, labor availability, and material requirements, businesses can proactively address capacity limitations and ensure smooth operations.

What If Simulations

Production planning and control tools facilitate scenario analysis and “what-if” simulations. Businesses can evaluate the impact of different factors like changes in demand, workforce availability, or machine breakdowns on their capacity. This helps in making informed decisions and developing contingency plans.

These tools support long-term capacity planning by considering factors such as market trends, growth projections, and strategic objectives. By aligning capacity with future demand, organizations can avoid overcapacity or underutilization of resources.

Capacity planning tools also enable businesses to monitor real-time production data and performance metrics. This allows for continuous improvement and optimization of the production process, identifying areas for efficiency gains and cost savings.

4. Production Scheduling Software

Production scheduling software is a vital component of production planning and control tools. It helps businesses efficiently manage their production processes by providing a systematic approach to scheduling production activities.

One key feature of production scheduling software is its ability to optimize production schedules. By considering factors such as available resources, production capacity, and customer demand, the software can generate schedules that maximize efficiency and minimize downtime. This helps businesses ensure that production targets are met while reducing costs and improving overall productivity.

Another important aspect of production scheduling software is its ability to track and manage inventory levels. By integrating with inventory management systems, the software can provide real-time updates on stock levels, allowing businesses to plan their production activities accordingly. This helps prevent stockouts or excess inventory, reducing wastage and improving cash flow.

Furthermore, production scheduling software enhances communication and collaboration among different departments involved in the production process. It provides a centralized platform where managers, planners, and workers can access and update production schedules in real-time. This ensures that everyone is on the same page and enables quick decision-making when unforeseen circumstances arise.

5. Quality Management Systems (QMS)

Production Planning and Control Tools are an integral part of Quality Management Systems (QMS). These tools play a crucial role in ensuring efficient and effective production processes while maintaining the highest level of quality standards. Here are 200 words about QMS and its relationship with Production Planning and Control Tools:

- Production Planning: QMS utilizes production planning tools to effectively schedule and allocate resources for manufacturing operations. These tools help in optimizing production processes, reducing bottlenecks, and ensuring timely delivery of products.

- Material Requirement Planning (MRP): MRP is a production planning tool used in QMS that helps in determining the materials required for production based on demand forecasts. It ensures that the right amount of materials is available at the right time, minimizing inventory costs and production delays.

- Capacity Planning: QMS incorporates capacity planning tools to analyze and optimize the production capacity of a company. It helps in balancing the workload, identifying potential bottlenecks, and ensuring that production resources are utilized efficiently.

- Workforce Management: QMS includes workforce management tools that aid in planning and scheduling labor resources effectively. These tools help in optimizing labor utilization, tracking employee performance, and ensuring that skilled workers are assigned to appropriate tasks.

- Quality Control Tools: Production planning and control tools within QMS also encompass quality control tools. These tools, such as statistical process control (SPC) and Six Sigma methodologies, help in monitoring and controlling production processes to ensure consistent quality output.

6. Lean Manufacturing Tools

Lean manufacturing principles focus on eliminating waste and optimizing processes to improve efficiency and reduce costs. Several tools are commonly used in lean manufacturing practices, including:

- Value Stream Mapping: Value stream mapping helps identify inefficiencies in the production process by visually mapping the flow of materials and information from supplier to customer. This tool enables organizations to identify areas for improvement and implement targeted process enhancements.

- Kanban System: The Kanban system is a visual scheduling tool that enables just-in-time (JIT) production by signaling when to replenish materials or start new production based on actual demand. This system helps minimize inventory levels while ensuring continuous flow in the production process.

- 5S Methodology: The 5S methodology focuses on organizing the workplace to optimize efficiency and productivity. It involves sorting, setting in order, shining, standardizing, and sustaining a clean and organized work environment.

- Kaizen: Kaizen refers to continuous improvement through small incremental changes in processes. It involves empowering employees at all levels to identify improvement opportunities and implement changes to enhance productivity and eliminate waste.

By implementing lean manufacturing tools, companies can streamline their operations, reduce lead times, improve product quality, and ultimately increase customer satisfaction.

PPC in Jewelry Manufacturing

- Production Planning and Control (PPC) plays a crucial role in jewelry manufacturing by ensuring efficient and effective production processes. It involves the coordination of various activities, such as material procurement, resource allocation, and scheduling, to meet production targets and deliver high-quality products to customers.

- The first step in PPC is demand forecasting, where historical data and market trends are analyzed to determine future product demand. This information helps in planning production quantities and scheduling resources accordingly.

- Once the demand is forecasted, the next step is capacity planning. It involves assessing the available resources, such as labor, machinery, and raw materials, to determine the production capacity. This helps in avoiding over-utilization or underutilization of resources and ensures smooth production flow.

- Material procurement is another crucial aspect of PPC in jewelry manufacturing. It involves sourcing high-quality raw materials, such as precious metals, gemstones, and findings, to meet production requirements. Timely procurement ensures uninterrupted production and prevents delays in fulfilling customer orders.

- Scheduling is an integral part of PPC, where production activities are sequenced based on resource availability and production priorities. It helps in optimizing production time and reducing bottlenecks. Additionally, it ensures that different jewelry pieces are produced in the right sequence, considering their complexity and requirements.

- Quality control is also a vital component of PPC in jewelry manufacturing. It includes inspecting raw materials, monitoring production processes, and conducting final inspections to ensure that finished products meet the desired quality standards. This helps in maintaining customer satisfaction and brand reputation.

Many Manufacturing hubs in SEEPZ Mumbai, Surat in India, Dubai Markets are hiring for PPC and other Jewellery jobs. Prepare your resume and get your dream job in this industry.

Conclusion

Production planning and control tools play a vital role in streamlining manufacturing processes and ensuring operational efficiency. Whether it’s an ERP system for integrated data management or lean manufacturing tools for waste reduction, these tools help manufacturers optimize their resources, improve productivity, reduce costs, and deliver high-quality products on time. By leveraging these tools effectively, organizations can gain a competitive edge in today’s dynamic business environment.