Platinum metal is a chemical element with the symbol Pt and atomic number 78. It is a dense, malleable, ductile, highly unreactive, precious, silverish-white transition metal. Its name originates from Spanish Platina, a diminutive of Plata “silver”.

Platinum is a precious metal that has been highly regarded for centuries due to its rarity and valuable properties. While it is commonly associated with jewelry and investment, platinum has also found significant use in various industrial applications. This blog explores the growing industrial use of platinum metal and its impact on different sectors.

The Many Applications Of Platinum Metal

Although over half of all platinum metal production is used to make jewelry, it is increasingly being used in the medical, electronic, automobile, defense, and aerospace industries. It is also a key catalyst in many industrial processes.

Today those features make platinum invaluable to a huge range of industrial processes and products, from fertilizers to fiberglass, anti-cancer drugs to thermocouples in furnaces and kilns.

Autocatalysts

Autocatalysts

Platinum is employed as a catalyst in many industrial processes.

- It is used to make detergents, fertilizers, plastics, explosives, and many types of acids.

- Platinum-iridium crucibles are used in industrial processes to make semiconductor crystals that produce laser light.

- Used to make high-quality glass for television tubes and flat-screen computer monitors.

Medical & Biomedical industry

Platinum has a wide range of applications in the medical field because it is chemically inert and a good conductor of electricity. Stents, catheters, guidewires, neuromodulators, defibrillators, and all pacemakers use platinum components because, like gold, it doesn’t react with the chemicals in human tissue but it is much harder-wearing than the yellow metal.

- It is used in electronic medical implants including pacemakers and hearing aids.

- Platinum electrodes are also being tested in clinical trials aimed at helping the victims of Parkinson’s disease.

- Surgically implanted stents are used to treat heart disease, and dental fittings are often made of platinum-iridium wire mesh.

- Drugs containing platinum are used to treat certain cancers. Platinum’s anti-cancer potential was first discovered in the early 1960s, with commercial production of cisplatin drugs starting the following decade.

Electrical and electronic use

- The late 20th Century’s revolution in digital data storage was enabled by platinum, coated onto the platters used in hard disc drives.

- Demand peaked in 2000, with ‘thrifting’ by technology manufacturers then coinciding with a slowdown in new HDD shipments.

- Platinum alloys often substitute for gold in electronic equipment. Today, the largest single application of platinum in the electronic industry is for the magnetic coating of computer hard drives.

- Platinum-cobalt alloys are slightly magnetic. Today more than 90% of all computer hard drives are coated with this alloy, which enables the disks to store larger amounts of information.

Chemicals industry

Again acting as a catalyst to boost the speed and efficiency of chemical reactions, platinum is essential in producing many key industrial, agricultural, and household chemicals.

- The greatest chemical demand for platinum comes from creating specialty silicones according to technology specialists Johnson Matthey.

- Platinum compounds are used in everything from sealants to electrical wire insulation, and lubricants to kitchen utensils.

- Petroleum refining – The most consistent industrial use of platinum over the last four decades is the oil refining industry uses the metal as a catalyst for ‘cracking’ low-grade fuel into more efficient forms including gasoline, diesel, and jet-engine fuel.

- Glass manufacturing – Holding and channeling molten glass requires tools that can both withstand temperatures of 1700°C and also avoid corroding or reacting with the silicates and other materials used. Fiberglass is produced by drawing the glass through a platinum sieve called a ‘bushing’.

Automotive/Automobiles Industry

Platinum alloys play an important role in the defense and aerospace industries because they are incorporated into jet and rocket engines, which work in extremely hot and corrosive conditions caused by burning fuels. Platinum alloys are also used to coat the nosecones of missiles.

- Platinum’s single heaviest use currently comes from the auto sector, where the metal is used to reduce harmful emissions, most notably from diesel engines.

- The small rocket motors that maneuver satellites into place are also made of platinum alloys.

- Used in the electronics of the engine, braking, and airbag deployment systems.

- Platinum alloys resist spark and heat damage, thus used to coat the tops of spark plugs.

- Platinum is a key component of the catalytic converters used to control automobile emissions.

- Placed in the exhaust system of a truck or car, a very fine coating of platinum speeds up the reaction of oxygen with both deadly carbon monoxide (CO) and hydrocarbons (so-called greenhouse gases), turning them into less harmful carbon dioxide (CO2) and water, and also reducing the output of sulfur particles.

- Platinum-based coatings protect jet-engine blades (temperatures reach 2000°C); found on the tip of high-performance spark plugs, and fuel-cell technology is a fast-growing alternative to gasoline and diesel combustion engines.

Glass Manufacturing

Glass manufacturing using platinum metal involves the utilization of platinum as a catalyst in various stages of the process. Platinum possesses exceptional properties that make it suitable for this application. Firstly, it has a high melting point, allowing it to withstand the high temperatures required for glass production. Secondly, platinum is highly resistant to corrosion and chemical reactions, ensuring the purity of the glass product.

Additionally, platinum’s catalytic properties aid in the refining and purification of raw materials, enhancing the quality of the glass. Its use in glass manufacturing contributes to the production of high-quality, durable, and optically clear glass products across various industries, including automotive, construction, and electronics.

Other Industrial uses of Platinum

- Platinum’s resistance to both corrosion and very high heat makes it ideal for a huge range of industrial sensors, from thermocouples in furnaces to exhaust-gas control systems and CO detectors in homes and offices, as well as high-spec laboratory equipment.

- Hydrogen is mixed with oxygen and passed over a platinum catalyst, speeding their chemical reaction and producing pure water plus electricity.

- Pure platinum is also used to make quality flutes. Though expensive, the density of the metal gives the flutes a distinctive tone.

Jewelry Making

Platinum, a rare and precious metal, has become increasingly popular in the world of jewelry making. Known for its durability, elegance, and resistance to tarnish, platinum is a favored choice for creating exquisite pieces. Jewelry makers value platinum for its malleability, allowing them to craft intricate designs and delicate details. Its lustrous white color complements various gemstones, enhancing their brilliance.

Platinum jewelry is highly sought after for its timeless appeal and investment value. Whether it’s engagement rings, necklaces, earrings, or bracelets, platinum adds a touch of luxury to any piece. Skilled artisans continue to explore the endless possibilities of jewelry making with this remarkable metal.

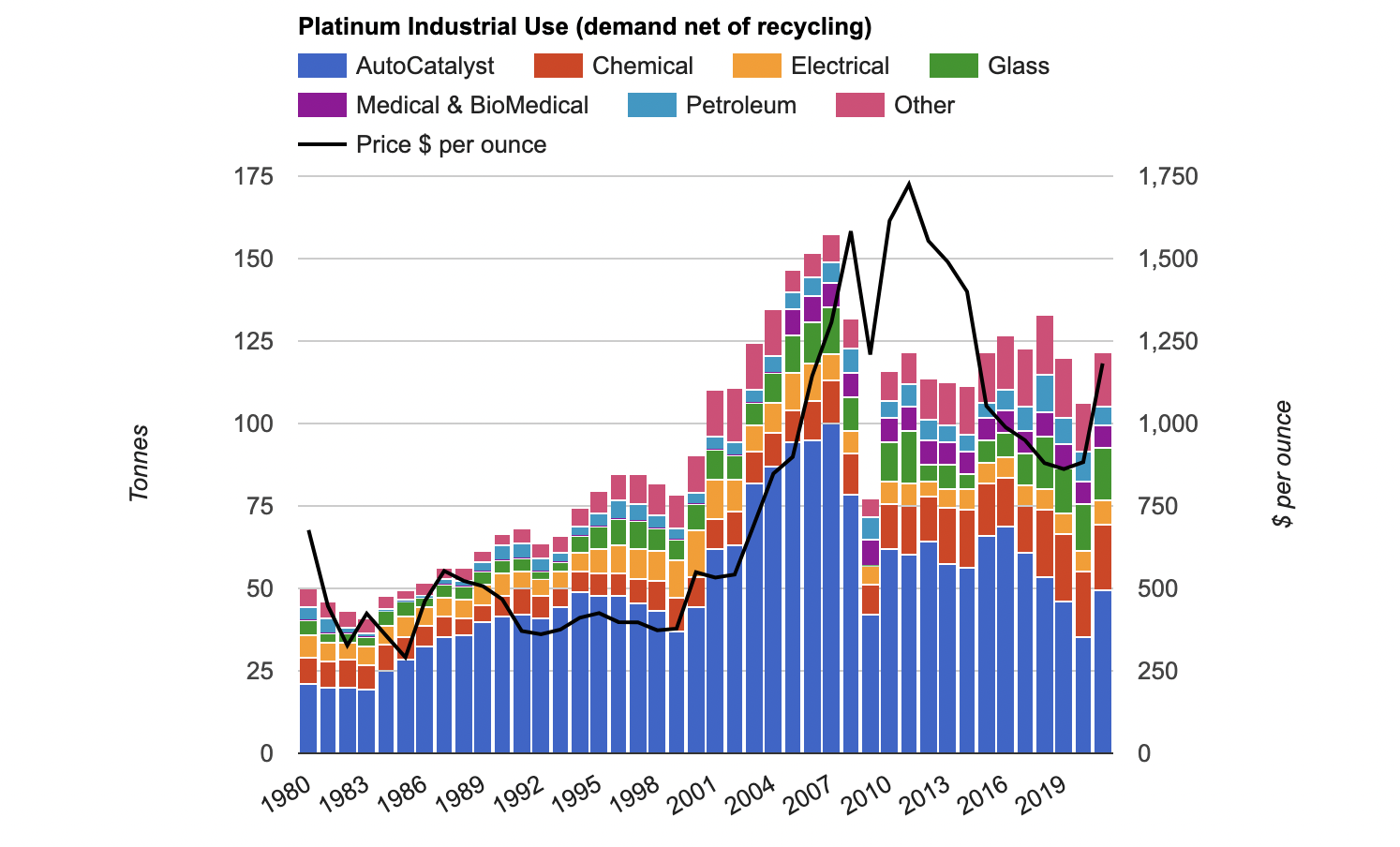

This interactive chart from BullionVault shows how platinum’s industrial use has changed and grown since 1980.

Using historic platinum data from refining and technology specialists Johnson Matthey, the infographic tracks demand for each year (in metric tonnes) against the annual average platinum price in US Dollars.

Outside of autocatalysts, each category of industrial use listed here saw demand in 2019 beat its previous half-decade average. But the Covid Crisis starting in March 2020 then crushed economic activity worldwide, driving autocat demand for the platinum rate to its lowest since the mid-1980s and hitting nearly every other source of industrial demand except electrical and electronics.

Now 2021 will see industrial platinum demand rise across every sector on Johnson Matthey’s forecasts, with autocat demand (still the largest of all platinum uses) rising 40% year on year.

Electrics and electronics use, net of the sector’s recycling flows will reach the greatest since 2007 while glass-making will match its record demand of 2011.

Most exciting, the growing ‘hydrogen economy’ needs increasing quantities of platinum to help create green electricity as a competitor and complement to battery-electric technologies.

Future use of Platinum Metal

Platinum, a precious metal valued for its rarity and unique properties, holds great potential for future applications across various industries. With advancements in technology and growing demand for sustainable solutions, the future use of platinum is expected to expand significantly.

In the automotive industry, platinum is already used in catalytic converters to reduce harmful emissions from vehicles. As the world shifts towards electric vehicles, platinum is expected to play a vital role in fuel cell technology, which converts hydrogen into electricity, offering a clean and efficient alternative to traditional combustion engines.

Moreover, platinum’s remarkable conductivity and resistance to corrosion make it an ideal material for various electronic devices. It can be utilized in advanced batteries, superconductors, and even in the development of quantum computers, contributing to faster and more efficient computing systems.

Additionally, platinum’s biocompatibility and resistance to oxidation make it a promising material for medical applications. It can be used in implants, pacemakers, and drug delivery systems, revolutionizing healthcare treatments and enhancing patient outcomes.

As research and innovation continues, we can expect to see its utilization in renewable energy technologies. Also in aerospace applications, and even in the production of sustainable chemicals. The future of platinum holds immense possibilities, paving the way for a greener, more advanced, and interconnected world.

Final Thoughts

In conclusion, platinum’s industrial applications have expanded significantly beyond its traditional use in jewelry and investment. Its unique properties are high catalytic activity, electrical conductivity, and resistance to corrosion. This makes it an invaluable material in various industries. From automotive catalysts to fuel cell technology, petrochemical processes to glass manufacturing, platinum plays a vital role in enhancing efficiency. Also it improved sustainability, and product quality across multiple sectors. As industries continue to evolve, the demand for platinum is expected to grow further. It is reinforcing its position as an indispensable metal in the modern industrial landscape.